Total Compliance

When it comes to keeping your pipeline online, our work is done safely, effectively, and with total compliance. We deliver maximum productivity on everything from comprehensive hot tap and line stop services to delivering a single fitting.

-

Always Responsive Always Committed

We’re dedicated to your success—whether we’re responding to an RFQ or working with you on a changing pipeline project schedule.

-

Dedicated Service Efficient Solutions

We tackle a range of hot tap and line stop service needs, providing quality services for the entire job.

-

Repairs & Upgrades To Stay Online

Whether you’re bringing in a new line or repairing an existing one, we help you maintain pipeline productivity.

-

Safety Comes First

Our standards go beyond customer safety requirements to continuously improve all aspects of HSE performance.

-

All Experts Zero Surprises

Our skilled technicians are highly trained to perform smooth execution with all the latest field equipment.

-

Smooth Execution Every Time

Our highly-skilled teams deliver world-class performance and seamless execution on every hot tapping & plugging job.

-

Get High-Quality Fittings

Our experts deliver the high-quality fittings you need for dependable performance on every hot tapping & plugging project.

-

Our Work Is Done By The Book

Our practiced experts uphold rigorous standards and maintain all the certifications needed to ensure complete compliance.

Hot Tap Systems

For Highly Productive Pipelines

Our technologies help mitigate operational issues, corrosion, downtime and low flow rates associated with liquid pooling and slugs.

Reliable Hot Tap

Fittings

We engineer and manufacture hot tap fittings of all sizes and specifications to ISO 9001:2015 quality.

- Designed to eliminate fabrication stress risers

- Engineered with integral fitting reinforcement

- Available in material trades from A234 WPB to

WPHY-70 - SureLoc® completion plug secured with segment rings

- No run-to-branch weld

Sizes from 1/2" to 36" diameter; up to 2,220 PSI

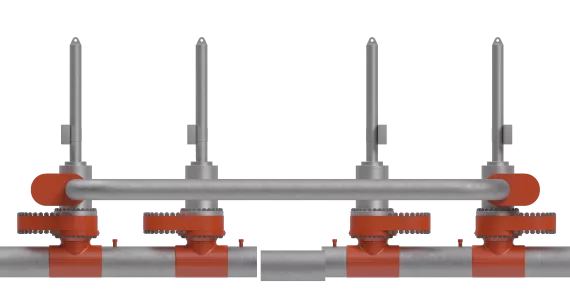

Line Stop Services That

Keep You Productive

Our line stop services maximize uptime with minimal impact to your ongoing operations. That's because our experts understand your objectives and provide the ideal solutions for your hot tapping & plugging project.

- Immediate callback and quotation

- A variety of line stop configurations

- Expert isolation consultant

- Extensive range of equipment

Sizes from 1/2" to 36" diameter; up to 2,220 PSI

Stocked and Ready So

You Waste Zero Time

We’re driven to provide superior support for your hot tapping & plugging operation. We maintain a wide-ranging inventory of hot tapping & plugging equipment—always available for same-day or next-day shipment. That means you get access to a wide selection of fittings, flanges, flow-through plugs, and other essentials available in a variety of sizes, materials, and configurations.

Pipeline Fittings

You Can Depend On

WeldFit brings skilled hot tapping & plugging expertise and the right equipment and fittings for every job. Our priority is your productivity. That means we manage your pipeline repair/expansion to ensure there’s no interruption of product flow.

- High-quality fittings designed and tested for reliable performance

- SureLoc® blind plugs and flow-through plugs

- Fittings for 4" through 48" pipe sizes (with ASME class 150, 300, and 600 flange)

- All 100% radiographically inspected

- All made in compliance with ISO 9001:2015

- All ASME B31.3, B31.4 and B31.8 certified

Maximum Productivity

At WeldFit, we have the expertise to optimize bypass operations for complex projects to keep you online. And our expert hot tapping & plugging technicians recommend the perfect solution for any application, executing the work seamlessly

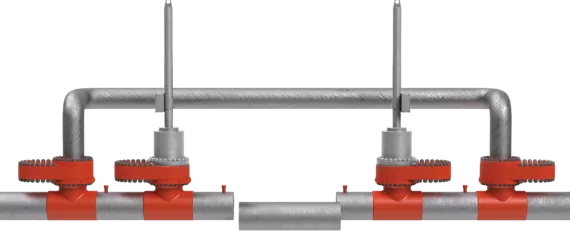

Bypass Through Housing

When reduced flow is acceptable and constricted flow is still adequate to maintain operational expectations, bypass through housing or the following method is recommended.

Bypass Through 3-Way Tee or Spool Adapter

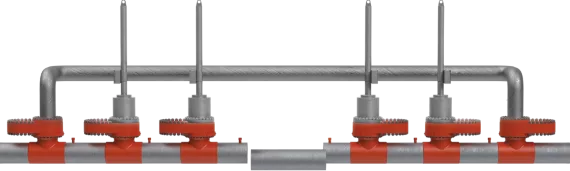

External Bypass

When full flow production is required to maintain operational expectations.

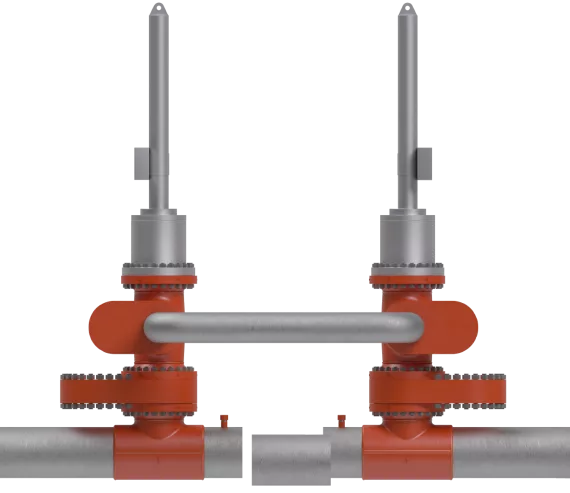

True Double Block & Bleed

A true double block & bleed has two seperate control bars that can actually provide the ability to reset if blowby occurs. Less expensive than other double block & bleed systems.

Keep your project safe and productive by putting WeldFit on your next hot tap or line stop project.

Committed To

Safety at the Highest Standards

WeldFit’s Target Zero program sets a roadmap for the organization to keep our employees, customers, partners, and host communities safe through best practices and protocols proven for over 50 years.

Target Zero

WeldFit ensures safety protocols with comprehensive, dedicated training for our hot tap and line stop crews. That means you get expert technicians who never compromise on safety.

- Job safety analyses

- Near-miss reporting and analytics

- In-house training and certification (classroom and hands-on instruction)

- Structured mentorship programs

- Annual safety audits and reviews

- Data-driven improvement systems

- Training/certifications through DOT, OQ, and NCCER

Certifications and Training

Our crews are certified in the entire pipeline intervention process, from efficient hot tap and line stop operations to comprehensive safety protocols.

- An integrated approach to the certification process, rotating technicians across a variety of projects, technical focuses, equipment, and problem-solving complexities

- Multilateral educational methods that combine classroom training, monitored hands-on instruction and extensive personal mentorship

- Annual audits and refreshers with every one of our technicians to ensure we’re meeting and advancing best practices

- No compromise when it comes to maintaining certifications with Department of Transportation standards for Operator Qualification (OQ), NCCER, and various regional safety councils

Reach Out

Book Our Services

We’re ready to work. Book our services by clicking here, emailing your specs to sales@weldfit.com or by calling 713-460-3700. We’re looking forward to getting started.