BUILT FOR INTEGRITY AND EASY INSTALLATION

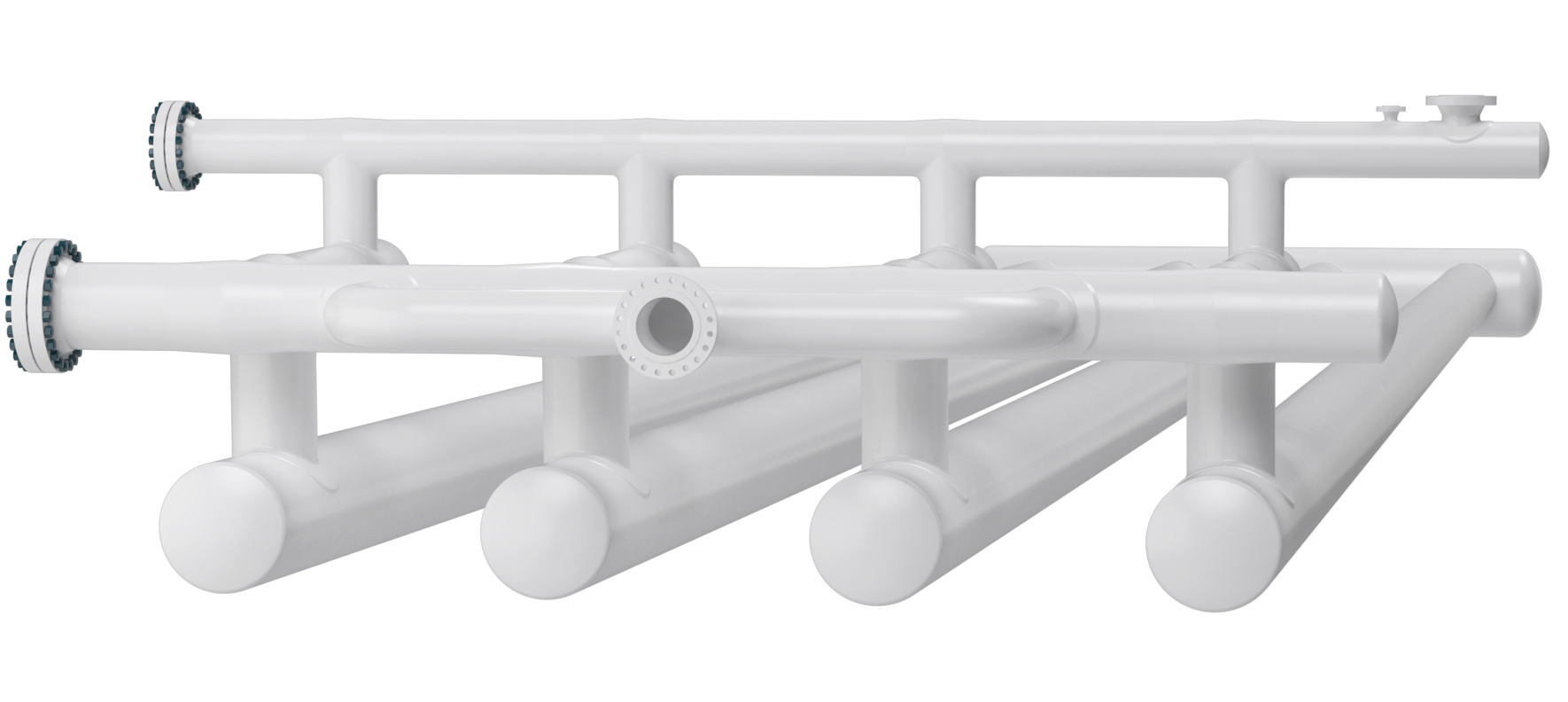

WeldFit specializes in engineering, manufacturing, and testing of a harp or finger-style slug catchers that perfectly balance your application’s efficiency, capacity, and economic demands.

MODULARITY

Designed and built for streamlined field installation and commissioning—from fitting-to-pipe welds to options for skid-mounting and custom connections. All Slug Catchers made in adherence to rigorous quality standards.

CAPACITY

Prevent system overload and keep your pipeline optimized with slug catchers that offer enough buffer volume to store the largest slugs in any system. We also engineer and manufacture high-capacity systems with ANSI 600# ratings, liquid volumes up to 50,000 BBL, and gas volumes up to 1 BCFD.

EASY INSTALLATION

Streamline installation and startup in the field with slug catchers configured and prepped for paint. Our modular systems are designed to be shipped and assembled on-site at your facility—we can even ensure short lead times.

CFD MODELING

WeldFit's team of experts can employ Computational Fluid Dynamics (CFD) modeling to diagnose and solve issues on your current slug catcher or to provide a process guarantee on our slug catcher.

The Strategic Selection is Always Standard...

- Standard or custom designs available for any application

- Shorter lead time through the use of standard designs

- Extrusion process eliminates expensive girth welds in the field

- Sludge management cleaning solutions available

- Lower cost of installation

- Primer coated for repainting, or per customer specifications

- Modular systems for more efficient shipping and assembly on-site

- Manufactured per applicable design codes and customer specifications

- Design standards:

B31.8, Sec. VIII Div. 1) - Pressure rating:

ANSI 150#, 300#, 600#, 900# - Temperature range:

-50° F to 150°

See more about our Pigging Technologies, including the SureLaunch® for ultimate efficiency and productivity.