Confident HSE Performance

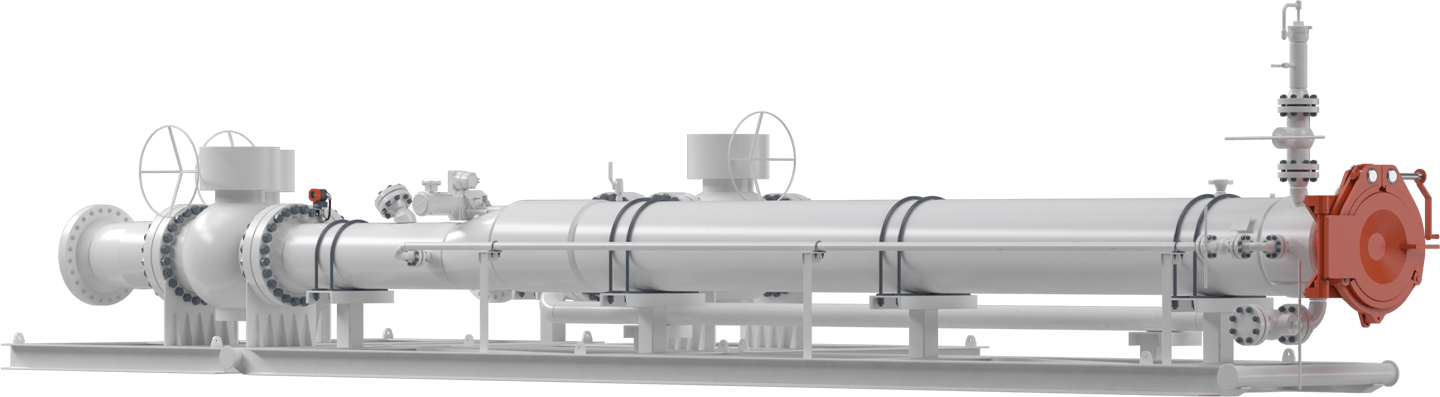

- The horizontal design eliminates the need for access platforms and lifting equipment, reducing safety risks and the cost of transportation and field installation.

- The electric drive system can be powered by 115 VAC or 24 VDC Class 1, Division 1 & 2 compliant power to eliminate supply gas, supply gas treatment, and emissions.

- All units are hydrostatic pressure tested in accordance with applicable codes.

- Each unit is designed to all applicable safety design factors and inspected in accordance with all applicable pipeline codes (B31.8, B31.4, B31.3, Sec. VIII Div. 1).

Stay Productive

From The Pipeline To The Plant

-

Lower Maintenance Costs

Extend valve life, saving money on replacement costs and system uptime.

-

Keep Safety On Track

Eliminate unsafe access platforms and continual opening.

-

Maximize Productivity

Launch in high or low flow conditions while monitoring and operating the system from remote locations.

-

Improve Capacity and Flexibility

The multiple-launch, electric drive system can launch up to seven pigs automatically.

-

Lower Operating Costs

Improve crew utilization and significantly reduce travel time and crew requirements.

-

Reduce Overall Emissions

Slash emissions with up to 85% reduction in closure openings.

-

Fast-Tracked Installation

Each unit comes primer coated or painted, configured, and ready to go.

-

Operate Remotely

Engage with the unit through remote access via Ethernet/IP address and robust data package.

Optimized Crew Deployment

- Remote monitoring allows for intelligent control that eliminates significant travel time.

- The receiver is designed to accommodate up to seven pigs or the length of typical in-line inspection tools.

- A robust data package is also provided for code compliance.

Are You Pigging Frequently Enough

If you are, you're getting higher flow rates. If you're not, we can help you get there.